Navigating the world of tool management can feel overwhelming, but understanding tool repair tags is a game changer for any workshop or industrial setting. These essential organizational aids offer a streamlined approach to tracking, maintaining, and ensuring the safety of your valuable equipment. From small independent garages to large manufacturing plants, implementing effective tool repair tags significantly boosts operational efficiency and reduces costly downtime. They provide immediate insights into a tool's status, history, and required maintenance, empowering teams to make informed decisions quickly. Discover how integrating robust tool repair tags into your daily operations can transform your workflow, enhance accountability, and extend the lifespan of your critical assets. This guide will help you unlock the full potential of organized tool management.

Unlocking Efficiency: The Power of Tool Repair Tags

Tool repair tags are indispensable tools used across various industries to manage, track, and identify equipment that requires servicing or has been sent for repair. These simple yet powerful labels provide crucial information about a tool's status, who initiated the repair, when it was sent, what issues it has, and its expected return. By integrating tool repair tags into your workflow, businesses can significantly enhance accountability, streamline maintenance processes, reduce downtime, and ensure compliance with safety regulations, ultimately optimizing their operational efficiency in 2026 and beyond. This approach helps maintain a clear and accessible record of every tool's journey through its service life.Tool repair tags are not merely pieces of paper; they are a fundamental component of effective asset management systems, offering a clear visual cue that instantly communicates the condition and location of vital equipment.Why Tool Repair Tags Are Essential for Every Workshop

Think about your tools as important investments. You want them to work when you need them and last a long time. Tool repair tags help you keep track of these valuable assets, ensuring they receive the attention they need to stay in top condition. These tags prevent misplaced items and help you understand the history of each tool's performance and maintenance. They empower your team to work smarter, not harder, by providing instant access to critical data.Tracking Your Assets with Tool Repair Tags

Every tool in your inventory tells a story, and tool repair tags help you read it. They provide a clear trail of where a tool has been and what has happened to it. Knowing when a tool was last serviced, what issues it had, and who worked on it gives you control over your inventory. This kind of detailed tracking helps prevent duplicate purchases and makes sure every piece of equipment is accounted for, saving your business time and money.Ensuring Safety and Compliance with Tool Repair Tags

When a tool is broken, it can be a hazard. Tool repair tags clearly mark equipment as unsafe or in need of attention, removing guesswork and protecting your team. This visible designation is crucial for preventing accidents and ensuring your workshop adheres to safety standards. Moreover, proper tagging supports regulatory compliance by maintaining accurate records of equipment inspections and repairs, which can be vital during audits.Choosing the Right Tool Repair Tags

Selecting the correct tool repair tags is vital for their effectiveness and longevity. Considerations include the tag's material, its durability, and the specific information it needs to convey. You want tags that can withstand your workshop's environment, whether it's greasy, dusty, or prone to extreme temperatures. Look for options that allow for clear, legible writing and can be securely attached to various types of tools and equipment. The right tag ensures information remains readable and accessible throughout the repair cycle.Here is a quick overview of important aspects related to tool repair tags:

Tag Aspect | Description | Benefit for Tool Repair TagsMaterial | Durable cardstock, plastic, or synthetic | Withstands harsh workshop conditions, prevents wear and tearInformation | Date in, issue, repair actions, technician, status | Provides clear history, aids quick decision-makingAttachment | String, wire, adhesive, zip-tie options | Securely affixes to various tool types and sizesVisibility | Bright colors, bold text, double-sided designs | Easy identification, quick status checks in busy environmentsCustomization | Pre-printed fields, writable surfaces, barcodes | Tailors to specific operational needs, enhances tracking systemsWhat Others Are Asking About Tool Repair Tags?

People often have practical questions when considering how to implement tool repair tags in their own settings. These common inquiries highlight the importance of clear processes and reliable products.What is the primary purpose of a tool repair tag?

The primary purpose of a tool repair tag is to clearly identify a piece of equipment that is broken, requires service, or is currently undergoing repairs. It removes ambiguity, ensuring that damaged tools are not mistakenly used and that the repair process is tracked efficiently from start to finish. This helps maintain safety and operational flow.What information should a tool repair tag include?

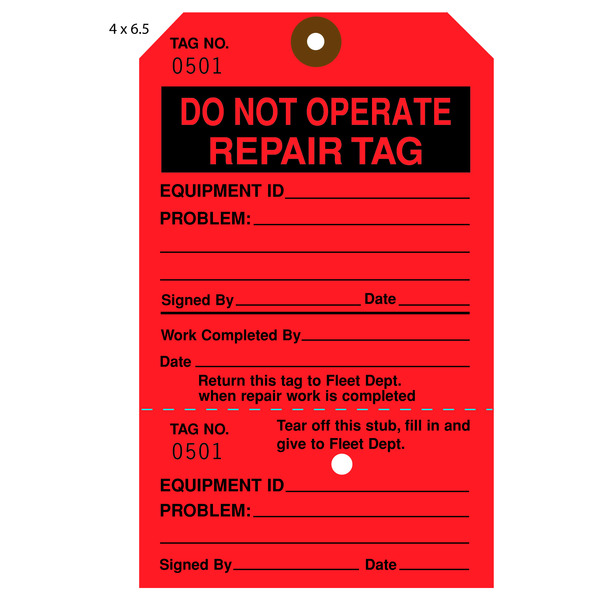

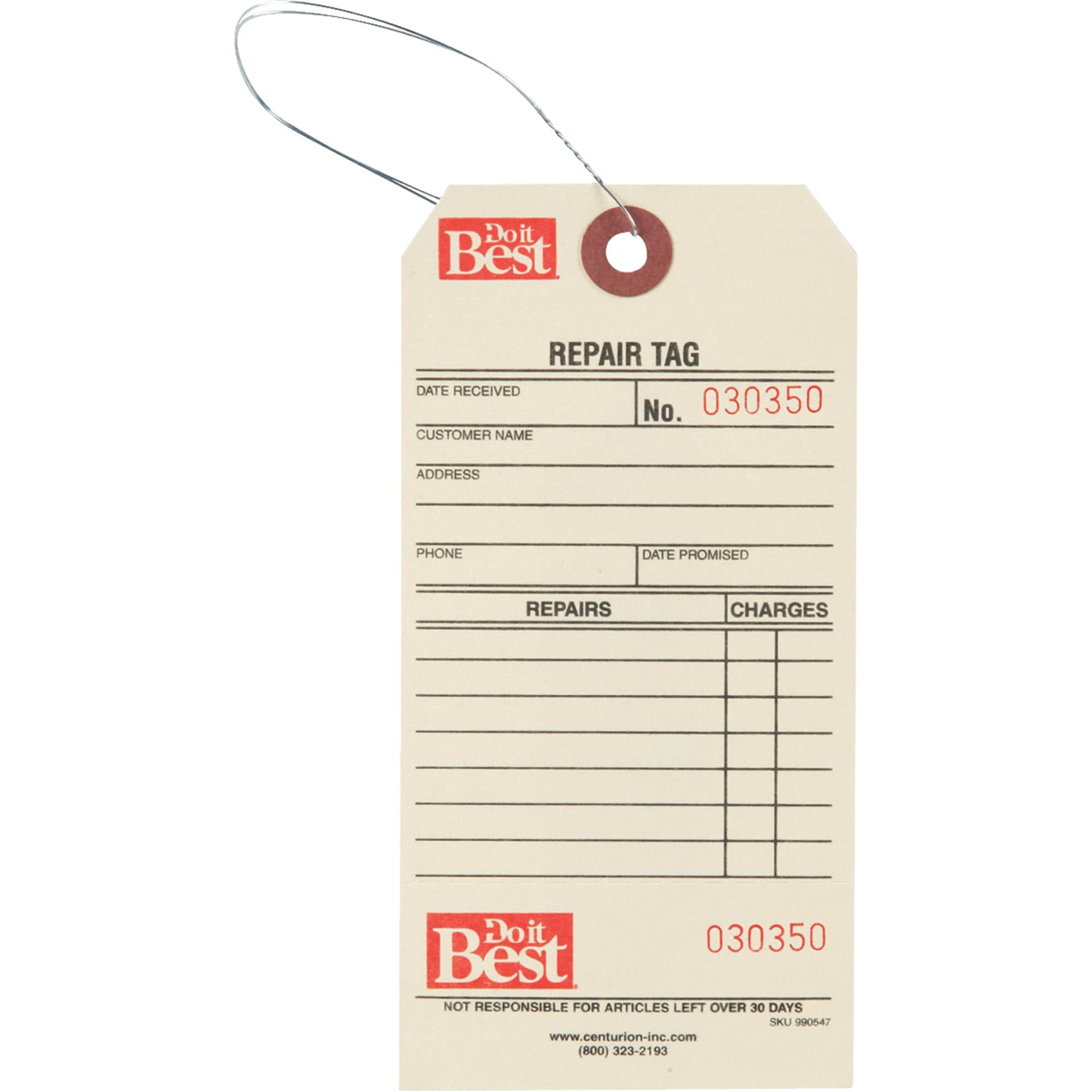

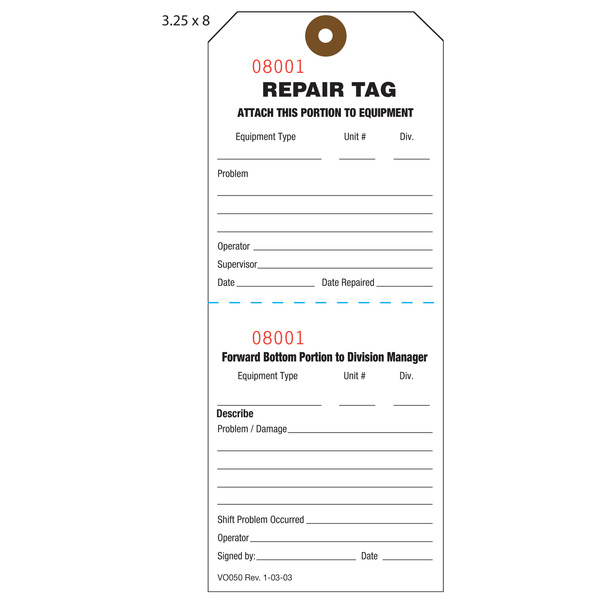

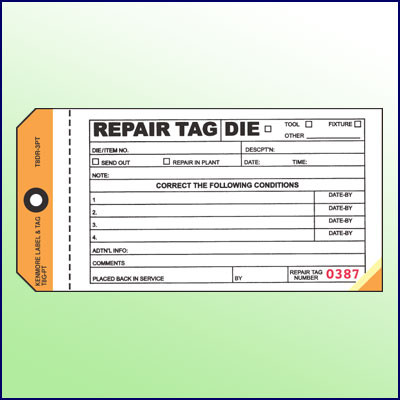

A comprehensive tool repair tag typically includes the tool's identification number, the date it was sent for repair, a description of the problem, the name of the person who reported the issue, and the repair technician's name. It should also specify the repair status, such as 'awaiting parts,' 'in progress,' or 'ready for collection,' ensuring all stakeholders are informed.How do tool repair tags improve workshop efficiency?

Tool repair tags significantly improve workshop efficiency by streamlining the repair workflow and minimizing communication gaps. They allow technicians to quickly understand a tool's issue and history, reduce time spent searching for information, and ensure tools return to service promptly. This organized system reduces bottlenecks and keeps operations moving smoothly.Are there different types of tool repair tags?

Yes, various types of tool repair tags exist, tailored to different environments and needs. Options include durable plastic tags for harsh industrial settings, laminated cardstock tags for general workshop use, and even tags with integrated barcodes or RFID chips for advanced tracking systems. Each type offers specific advantages in terms of durability and data capture capabilities.How often should tool repair tags be updated?

Tool repair tags should be updated immediately whenever a tool's status changes during its repair cycle. This means marking the tag when the repair begins, when parts are ordered, upon completion, and when the tool is returned to service. Regular, immediate updates ensure accurate information and prevent misunderstandings about a tool's availability.FAQ About Tool Repair Tags

Understanding the fundamentals of tool repair tags helps you grasp their immense value.What are tool repair tags?

Tool repair tags are physical labels attached to equipment indicating it needs repair or is currently being serviced. They contain critical information like the problem, date, and repair status. These tags ensure clarity and prevent the misuse of faulty tools, supporting safe and efficient operations.Who uses tool repair tags?

Workshops, manufacturing facilities, construction companies, maintenance departments, and rental businesses widely use tool repair tags. Any organization managing a fleet of tools or equipment benefits from these tags to streamline their repair and maintenance processes, ensuring optimal asset management.Why are tool repair tags important?

Tool repair tags are important because they enhance safety by identifying damaged equipment, improve organizational efficiency by tracking repair progress, and reduce downtime. They foster accountability, prevent miscommunication, and ultimately extend the lifespan of valuable tools, leading to significant cost savings.How do I implement tool repair tags effectively?

To implement tool repair tags effectively, choose durable tags, standardize the information included, and train your team on their proper use. Create a clear process for tagging tools, updating status, and removing tags post-repair. Consistent application is key to maximizing their benefits and maintaining an organized system.Summary of Key Points about Tool Repair Tags

Tool repair tags are indispensable for efficient and safe tool management. They provide a clear system for tracking equipment status, ensuring timely repairs, and enhancing workplace safety. By effectively using these tags, businesses reduce downtime, optimize operational workflows, and extend the life of their valuable tools. Implementing durable, informative tool repair tags with clear protocols empowers teams, improves accountability, and drives significant savings in maintenance and replacement costs. Embrace tool repair tags to transform your asset management strategy.Streamlined tool tracking, Enhanced safety compliance, Reduced equipment downtime, Improved workshop organization, Clear repair status identification, Extended tool lifespan, Boosted operational efficiency with tool repair tags.

Amazon Com Juvale Repair Tags For Equipment 3 X 5 75 In Red 100 AC SL1500 Repair Tags Equipment Repair Tags In Stock ULINE Ca G 3035Premium Vector Equipment Repair Tag Vector Front And Equipment Repair Tag Vector Front Back Templates Three Different Designs Isol 992073 100

Custom Repair Tags St Louis Tag Image13762 Tool Repair Equipment Repair Tag Kenmore Label Tag T8O TR Inspection 4 Year Maintenance Metal Tag SKU TG 339 B Tg 339 B 24 2 Industrial Repair Tags Equipment Repair Tags Repair Inspection Status Record Tag TG 0720

REPAIR TAG EQUIPMENT ID With Stub Numbered 2 Places Strung 5 75 X REPAIR TAG EQUIPMENT ID With Stub Numbered 2 Places Strung 5 75 X 2 875 Manila Cardstock Pack Of 25 Tags 04c655b2 D09a 4928 Bd05 Amazon Com 100 Pack Repair Required Tags Yellow Service Tags For AC Industrial Repair Tags Equipment Repair Tags Repaired Repair Tag With Stub 5754 C Amazon Com Juvale 100 Pack Repair Required Tags Yellow Service Tags 71VAndiN PL

Industrial Repair Tags Equipment Repair Tags Danger Equipment Needs Repair Tag TG 0550 Repair Tag Seton Seton Carbonless Copy Tags Nct23 Lg Dam 3624126 Custom Repair Tags St Louis Tag Image27640 Custom Repair Tags St Louis Tag Image22434

PolyTag Equipment Repair Tag Visual Workplace Inc 55 4010 6253 RP102 Repair Tag ID 600x600 Industrial Repair Tags Equipment Repair Tags Repaired Plastic Tag T Box 023 Repair Required Tags Yellow Maintenance Required Tag 100 Pcs Service AC SL1500 Industrial Repair Tags Equipment Repair Tags Fluorescent Vinyl Repair Tag Tg 0197

Repair Quality Control Round Hang Tag Creative Safety Supply PS26010 4X6 Custom Repair Tags St Louis Tag Image13764 Repair Tag Equipment Status Safety Tag TRS242 TRS2422 Equipment Repair Tags 0000252 Equipment Repair Tags

Equipment Servicing Tags Power Tool Inspection Tags Equipment 847345 Repair Tags A Pack Of Equipment Service Repair Tags Repair Box Lockout Tag T Box 009 Industrial Repair Tags Equipment Repair Tags Ready To Rent Tag Tg 1586 Centurion 1 Part Repair Tag With Wire For Tools Numbered Pack Of 1000 Centurion 2 7 8 In 5 3 4 In Repair Tag 20e376bc B0b6 4410 Abd3

Tool Repair Equipment Repair Tag Kenmore Label Tag T8DR 3PT 100 Pack Repair Required Tags Yellow Service Tags For Broken Equipment 100 Pack Repair Required Tags%2C Yellow Service Tags For Broken Maintenance (3 X 6 In) Custom Repair Tags St Louis Tag Image14300 Repair Tags Maintenance Tags Equipment Repair Tags N4331

Industrial Repair Tags Equipment Repair Tags Repaired Vinyl Inspection Tag Tg 1286 Tear Off Jumbo Maintenance Repair Tags Seton Canada Seton Ca Tear Off Jumbo Maintenance Repair Tags Tyvek Mm928 Lg Dam 3685358 Tool Repair Equipment Repair Tag Kenmore Label Tag T8Y MR

.jpg)